Chitosan Material

______

Chitosan for Material Specifications: A Comprehensive Guide

We Tailor Chitosan to Meet Demands

A critical driver for the surge of interest in chitosan is its ability to be tailored during the preparation process. By adjusting parameters such as the degree of deacetylation and molecular weight, suppliers can fine-tune essential characteristics:

| Property | Influence on Material Specification |

| Degree of Deacetylation | Affects solubility, reactivity, and bioactivity |

| Molecular Weight | Impacts viscosity, mechanical properties, and film strength |

| Viscosity (@1.0% solution) | Impacts molecular weight , mechanical properties, and film strength BIO21 Chitosan high Viscosity : More than 4000,4000-2000,2000-1000 cPs Medium Viscosity : 1000-600 600-300,300-100 cPs Low Viscosity : 100-20, 5-10 cPs |

| Purity Level | Determines suitability for medical, cosmetic, or food applications |

Each specification can be optimized for a specific end-use, unlocking possibilities for products previously limited by the constraints of traditional materials.

BIO21 Chitosan material specification %DD (Degree of Deacetylation) : Viscosity

| Type ; Alpha/Beta (source) | %DD (Degree of Deacetylation) | Viscosity @ solution 1.00% (cPs) | ||

| High | Medium | Low | ||

| >4000,4000-2000, 2000-1000,1000-600 | 600-300,300-100 | 100-20,less than 20 | ||

| Shrimp shells | more than 90 between 80-90 less than 80 | NA | Y | Y |

| Crab shells (blue crabs) | Y | Y | Y | |

| Crab shells(snow crabs,Alaska) | Y | Y | Y | |

| Squid pen | Y | Y | Y | |

BIO21 Chitosan material specification %DD (Degree of Deacetylation) : MW (Molecular Weight)

| Type ; Alpha/Beta (source) | %DD (Degree of Deacetylation) | MW (Molecular Weight (kDa) | ||

| High | Medium | Low | ||

| >2000,2000-800 | 800-500,500-125,15-80 | 80-30,30-10 | ||

| Shrimp shells | more than 90 between 80-90 less than 80 | NA | Y | Y |

| Crab shells (blue crabs) | Y | Y | Y | |

| Crab shells(snow crabs,Alaska) | Y | Y | Y | |

| Squid pen | Y | Y | Y | |

Chitosan has found its place as one of the most versatile and sustainable biopolymers, capturing interest from industries ranging from pharmaceuticals to packaging. Its incredible adaptability comes from its unique structural properties and environmentally friendly origins, making it a standout candidate for consideration in modern material specifications.

What exactly makes this natural polymer such a compelling material, and how does it fit into the demands of contemporary products and applications? An in-depth look uncovers why specifying chitosan is gaining momentum among engineers, designers, and decision-makers determined to blend performance with responsibility.

The Science and Origin of Chitosan

Few materials possess a story as interesting as chitosan’s. Derived primarily from the shells of crustaceans like shrimp, crabs, and even lobsters, chitosan represents a remarkable feat of natural chemistry. Through a process called deacetylation, chitin – a naturally abundant biopolymer also found in fungi and insects – is chemically altered to produce chitosan, which is soluble in acidic environments and brimming with functional groups that enhance its usefulness.

Its molecular structure, rich with amino groups, endows it with flexibility for chemical modification. This is why it adapts so easily to the physical and chemical specifications needed across industries.

Physical and Chemical Properties That Matter

Material specification demands careful attention to detail, especially for products where performance and consistency aren’t negotiable. Chitosan stands out due to several key characteristics:

- Biodegradability: It breaks down naturally, avoiding environmental accumulation.

- Non-toxicity: Widely regarded as safe, making it attractive for food, pharmaceutical, and biomedical uses.

- Antimicrobial activity: The presence of positively charged amino groups enables disruption of microbial cell membranes.

- Film-forming ability: Creates transparent, flexible films suitable for coatings and packaging.

- Reactivity: Easily functionalized, offering an adaptable platform for composite materials.

These attributes set chitosan apart from many synthetic polymers and even some natural alternatives.

Applications Reinvented with Chitosan

Chitosan’s rise in the world of material specification is largely due to the remarkable range of products improved or reimagined with its involvement:

1. Biomedical Engineering: From wound dressings and sutures to drug delivery vehicles, chitosan’s biocompatibility and ability to accelerate healing make it a desirable alternative to synthetic polymers. It can be used as a scaffold for tissue engineering or as a component in hydrogels, providing controlled drug release with minimal side effects.

2. Water Treatment: Acting as a natural flocculant, chitosan is used to purify drinking water, remove heavy metals, and trap dyes in industrial effluents. Its positive charge attracts negatively charged particles, efficiently aggregating and separating out impurities.

3. Food Packaging: The film-forming properties and antimicrobial activity of chitosan combat spoilage and extend shelf life in food storage. Packaging materials derived from chitosan are biodegradable, aligning with the push for sustainable solutions across global markets.

4. Agriculture: Coatings for seeds and crops can increase resistance to diseases and promote plant growth without resorting to synthetic chemicals.

5. Cosmetics: In skincare and haircare, chitosan functions as a moisturizer, protective barrier, and carrier for active ingredients.

This broad appeal is pushing manufacturers and innovators to rethink what materials can offer in terms of both function and responsibility.

Navigating Standards and Sourcing

With so much potential, specifying chitosan demands attention to both its source and the standards it must meet. Supply chains for chitosan now span the globe, but the differences in processing methods and raw material origins matter.

Considerations when sourcing chitosan for a new material specification:

- Origin of raw material (shrimp, crab, fungal sources) to minimize allergens or comply with vegan labeling.

- Degree of purification needed for sensitive applications such as pharmaceuticals.

- Documentation and traceability to ensure regulatory compliance.

Certifications such as ISO 13485 (medical devices) or even food-grade standards can support the selection process, lending confidence to developers and clients alike.

Addressing Challenges in Specification

Every innovation brings its own set of challenges. When specifying chitosan, a few questions often arise:

How consistent is the material from batch to batch? Since chitosan is naturally derived, variations in season, species, and processing can affect properties. Strong quality control and close relationships with suppliers are key to maintaining reliability.

What about allergic reactions? For food and biomedical applications, the possibility of allergens from shellfish sources must be managed. Some suppliers now offer chitosan from fungal sources, which are intrinsically allergen-free.

How does it compare with established materials? Chitosan often exceeds synthetic polymers in environmental performance and sometimes in biocompatibility. For mechanical strength, blending with other biopolymers or adding nanocomposites can boost its profile.

Examples of Specification in Action

To illustrate how chitosan is specified, here are common criteria designers might request when ordering for different sectors:

| Application | Key Chitosan Specifications |

|---|---|

| Biomedical | High degree of deacetylation, ultra-high purity, specific molecular weight |

| Food Packaging | Intermediate degree of deacetylation, food-safe certifications, approved additives or blends |

| Water Treatment | Lower purity acceptable, bulk form, high molecular weight |

These real-world requirements show the flexibility available for targeting chitosan’s properties toward a project’s demands.

The Sustainability Angle

Momentum for eco-friendly solutions is undeniable, and chitosan fits into this movement effortlessly. Unlike petroleum-based plastics or non-renewable composites, chitosan comes from abundant waste streams—the shells left after seafood is processed, or biomass cultivated with minimal impact. Its lifecycle is notably gentle, breaking down into harmless substances at the end of use.

This advantage isn’t just good for the planet; it helps companies meet regulatory requirements and market their products to increasingly sustainability-minded consumers and clients.

Practical Tips for Material Selection

Those ready to specify chitosan for materials development can start by asking a few targeted questions:

- What are the performance goals – is barrier resistance, mechanical strength, flexibility, or antimicrobial activity most important?

- What regulatory or labeling requirements must be satisfied?

- Is end-of-life biodegradability a must, or can blends and coatings be considered?

Starting with these prompts encourages collaboration with suppliers to match the right grade of chitosan to the needs at hand.

A systematic approach often follows these steps:

- Identify performance criteria and regulatory needs.

- Request technical datasheets and sample analysis from reputable suppliers.

- Test in application to confirm properties and performance.

- Scale sourcing to align with production requirements.

Collaborative relationships with suppliers and end-users will help refine the material specification process, ensuring smooth integration into broader manufacturing strategies.

The Future of Chitosan in Material Design

Interest in chitosan is only set to accelerate. Ongoing research into blends with nanomaterials, unexpected sources (like mushrooms), and new forms – from aerogels to hydrogels – promises even greater specificity for advanced applications. Government support for biobased materials and rising consumer preference for sustainable products will only drive greater adoption.

Its inherent adaptability will continue to allow chitosan to keep pace with technological trends, regulatory demands, and the goals of forward-thinking product teams determined to balance innovation with responsibility.

The potential for chitosan within material specification lies not just in its technical features or sustainability story, but in its invitation to rethink what materials can accomplish for both people and the planet. As the world looks for smarter solutions, chitosan will remain a compelling option at the forefront of responsible material development.

Chitosan material product specification

The main properties;

of Chitosan product specifications are following;

- Degree of Deacetylation (%DD)

- Molecular Weight (MW)

- Viscosity

- Raw material source (the shells of sea creatures (Crustacea Malacostraca)) / Alpha and Beta type Chitosan .

These of (1) %DD, (2) MW, (3) Viscosity , and (4) raw material sources are key factors of the active or main functions of the Chitosan application or the final product

The other significant product properties;

of Chitosan product specifications are heavy metals, microbiological factors, Ash content, bulk density / tapped density, solubility, turbidity, and moisture

Chitosan grade

All properties of Chitosan material product specification combined are identified to the Chitosan grade

- Food grade / dietary supplement grade

- Medical device grade / Pharma grade

- Agricultural use (grade)

- Industrial use (grade)

Chitosan material product specs category, which is based for the applications

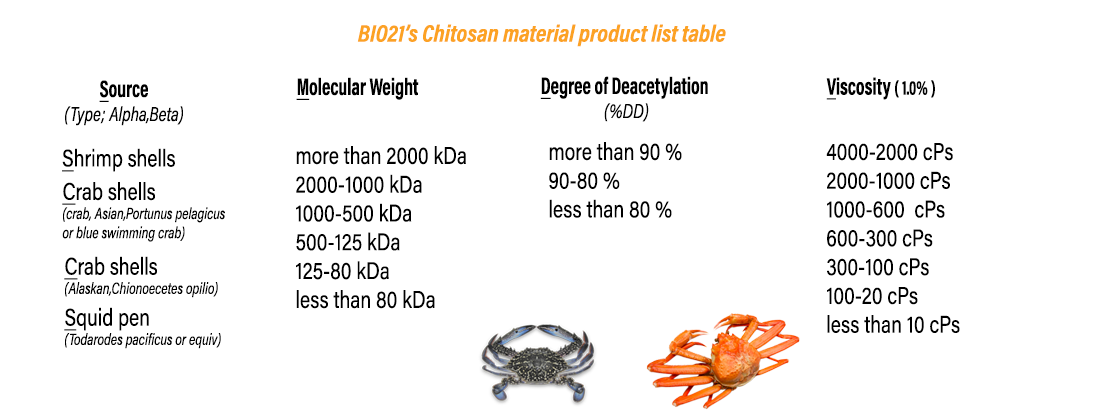

Product variance matrix by %DD : Molecular Weight or Viscosity : Sources

- High, Medium, and Low (cPs) Viscosity

- High, Medium, and Low (kDa) Molecular Weight (MW)

- 3 ranges of Degree of Deacetylation %DD (less than 80, between 80-90, more than 90)

- Sources (blue crab shells, Snow crab shells , Shrimp shells,Squid pen)

Source / Type (Alpha and Beta ) Chitosan

Shrimp shells

Crab shells (Crab, Asian, Portunus pelagicus / blue swimming crab)

Crab shells (Crab, Alaskan, Chionoecetes opilio)

Squid pen (Todarodes pacificus or equiv)

Raw materials, snow crab (Opilio crab and Alaska/King crab) shells from our GMP food processing factory

Molecular Weight (MW) Chitosan

High MW more than 2000 kDa, 2000-1000 kDa

1000-500 kDa

500-200 kDa

200-80 kDa

80-30 kDa

Low MW less than 30 (30-10)

Viscosity (solution 1.0%) Chitosan

High viscosity Chitosan , 4000-2000 cPs, 2000-1000 cPs

900-600 cPs

600-300 cPs

300-100 cPs

100-20 cPs

Low viscosity Chitosan less than 10 cPs (~ 5 cPs)

Degree of Deactylation (%DD) Chitosan

More than 90

90 - 80

Less than 80